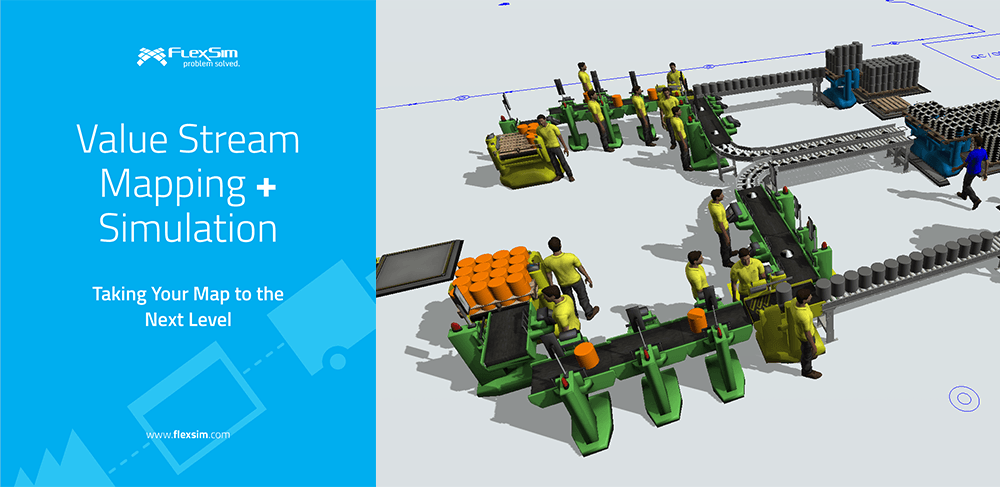

VSM + Simulation

Taking your map to the next level!

Where does simulation fit in with (and how does it benefit) a Lean process improvement analysis? In this eBook, we examine how simulation compares and contrasts with value stream mapping (VSM)—and show why simulation products like FlexSim are a great way to take your project to the next level.

In just 15 minutes, you’ll discover:

- A (very brief) overview of value stream mapping and its advantages and disadvantages.

- The three big ways that simulation overcomes some of the limitations of value stream mapping.

- A case study with Advanced Process Optimization, Inc. showing how simulation can reinforce traditional Lean/Six Sigma techniques.